Engineered Induction Systems.

Proven Results.

Engineered to improve efficiency, consistency,

and control at every heating process.

Engineered Options for Every

Heating challenge

Every Himmelwerk system is built on decades of engineering experience and tuned for exceptional control. These four product series form the core of our offering — adaptable, proven, and ready to meet the demands of complex applications.

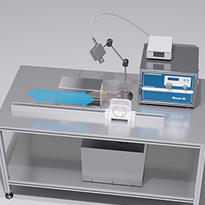

HU Series

Compact. Reliable. Adaptable.

The HU Series offers flexible power delivery in a compact design, ideal for space-conscious labs and manufacturing environments.

i Series

Digital Control for Complex Workflows.

With smart interfaces, real-time monitoring, and data-integrated performance, the i Series is a favorite among researchers and testing teams.

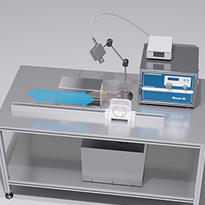

SINUS Series

Maximum Consistency. Specialty Materials.

Designed for sensitive materials and uniform heating, the SINUS Series ensures consistent, repeatable results — test after test.

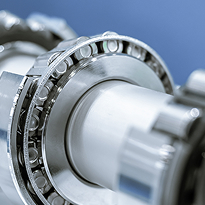

MU Series

More Power, deeper heat penetration

The MU Series are our medium frequency units, ideal for bigger workpieces or thicker materials and larger production lines.

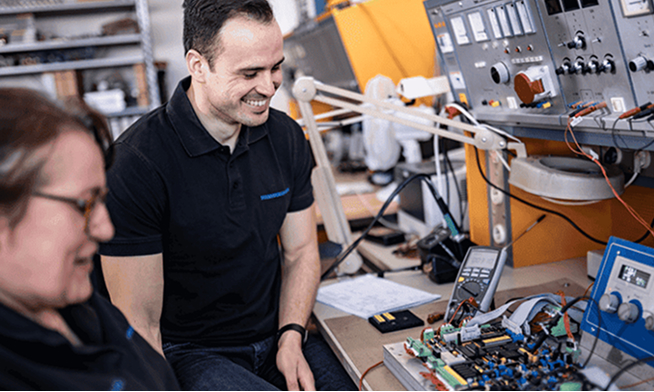

Top Engineering

Teams Choose Himmelwerk

Custom Heating Systems – carefully matched to each application. Himmelwerk’s consultive approach increases speed, efficiency and throughput

Megahertz Heating Advantage

Reach higher frequencies for greater surface-level control and responsiveness.

Tailored, Not Turnkey

Every system is selected and configured based on your process requirements.

Precision That Scales

From single-part tests to full-scale production, Himmelwerk solutions evolve with your operation.

Engineering-First Approach

Work directly with application engineers who understand your industry.

Trusted in North America and Beyond

In use by universities, labs, and manufacturers worldwide.

Find the right induction solution

Himmelwerk helps identify the best solution for the process. Use the form below or call directly at (947) 263-0444

Process Precision. Himmelwerk Systems Deliver.

Himmelwerk’s induction heating systems are trusted worldwide for accuracy, reliability, and adaptability. Our proprietary technology delivers precise, surface-focused heating — ideal for materials and components where traditional high-frequency systems fall short. Whether improving process control, reducing energy consumption, or optimizing cycle times, Himmelwerk helps you heat smarter – with solutions tailored to the exact application.

Tailored heating solutions

for process optimization

Engineering teams, researchers, and manufacturers across industries trust Himmelwerk. Whether testing materials, assembling components or producing at scale, solutions are tailored to meet performance requirements.

Metallurgical Testing Labs

Control surface-level heating for yield, torsion, and failure testing.

Materials R&D Facilities

Support innovation with finely tuned heat input for experimental materials.

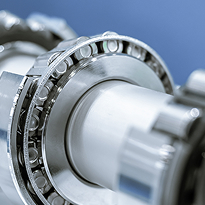

Automotive & Aerospace Components

Apply consistent heat for joining, forming, or thermal conditioning.

Electronics Manufacturing

Enable precision soldering, bonding, and microcomponent processing.

Medical Device Fabrication

Maintain uniformity for sensitive materials under strict tolerances.

Industrial Equipment Assembly

Handle brazing, shrink fitting, and structural joining with confidence.

Metallurgical Testing Labs

Control surface-level heating for yield, torsion, and failure testing.

Materials R&D Facilities

Support innovation with finely tuned heat input for experimental materials.

Automotive & Aerospace Components

Apply consistent heat for joining, forming, or thermal conditioning.

Electronics Manufacturing

Enable precision soldering, bonding, and microcomponent processing.

Medical Device Fabrication

Maintain uniformity for sensitive materials under strict tolerances.

Industrial Equipment Assembly

Handle brazing, shrink fitting, and structural joining with confidence.

Tailor the right solution for the process.

Himmelwerk is here to help identify and implement the right system matched to process requirements.