Discover Our Lineup of Precision Induction Systems

At Himmelwerk, our induction systems are engineered to deliver precision, control, and repeatability, all tailored to the demands of your specific heating process.

Explore our core product lines below and then reach out to our team to build your tailored heating solution today.

Core Induction System Series

Explore our lineup of high-frequency and medium frequency converters, each engineered for specific applications and levels of performance, from R&D labs to industrial-scale production, all rated for a 100% duty cycle.

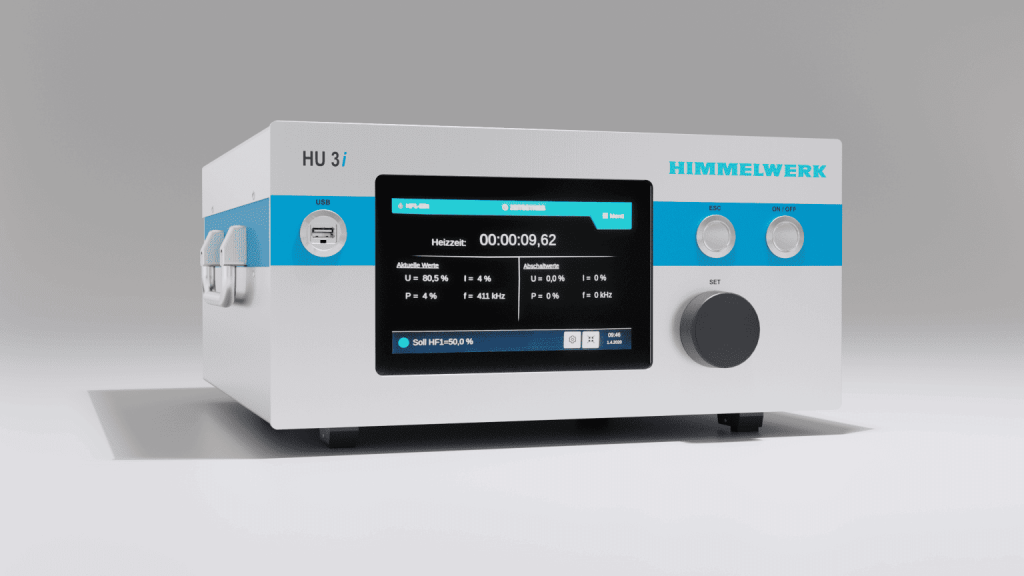

HU series

Compact Power, high frequencies,

ideal for smaller applications

The HU series provides excellent value for money, great connectivity options and a number of smart features making it ready for the challenges of industry 4.0, all in a small, table top compatible form factor.

HU S series

Maximum Power, high frequencies,

ideal for full scale production

The HU S series is the power house of high frequency induction. With up to 250 kWh of power and all the modern connectivity options you’ll ever need, it is a great choice for integration into your automated production site.

i SERIES

Smart Induction,

Seamless Integration

The i Series is Himmelwerk’s most intelligent converter, designed for applications that demand both precision and process control. With integrated interfaces and real-time data tracking, it’s the ideal choice for automated environments, research labs, and advanced production systems.

SINUS series

high and medium frequencies

for specialized applications

The Sinus Series is the true jack of all trades with a right converter for every job you throw at it. The models differ strongly in their configuration to suit the different specialties/niches they are designed for.

MU series

Maximum Power at medium frequencies

for larger applications

The MU Series delivers medium frequency induction heating designed for larger components and deeper heat penetration. With power levels from 25 to 250 kW, these cabinet-based systems are ideal for industrial-scale processes like forging, shrink fitting, and hardening, where thermal depth and mass heating are essential.

MU R series

Medium frequencies

compact form factor

The Devices of the MU R Series deliver medium frequencies at a small and easy to handle form factor. Great for table top use or for integration into mobile workstations or smaller automation systems.

You’re not sure which induction generator fits your needs? We’re happy to advise you

system components & Specialized equipment

Complete your Himmelwerk system with accessories designed for performance, measurement, and support. From inductors to melting plants, each component is engineered for seamless integration and precision heating control.

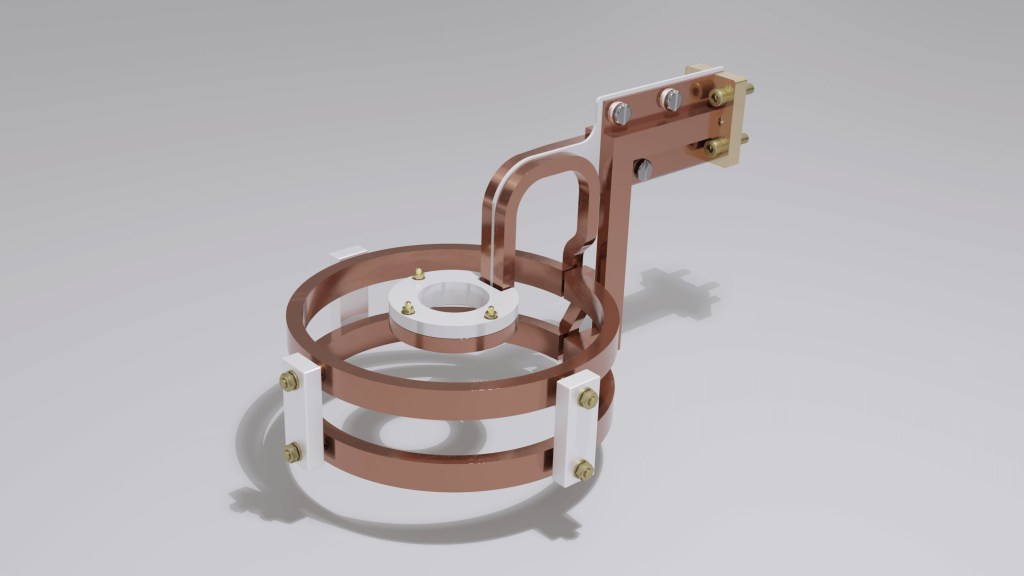

Inductors & Outer Circuits

Precision Coils for Reliable Heating Performance

We offer custom-wound inductors and matched outer circuits designed to fit your part geometry and frequency range. Every inductor is optimized for process stability and consistent results.

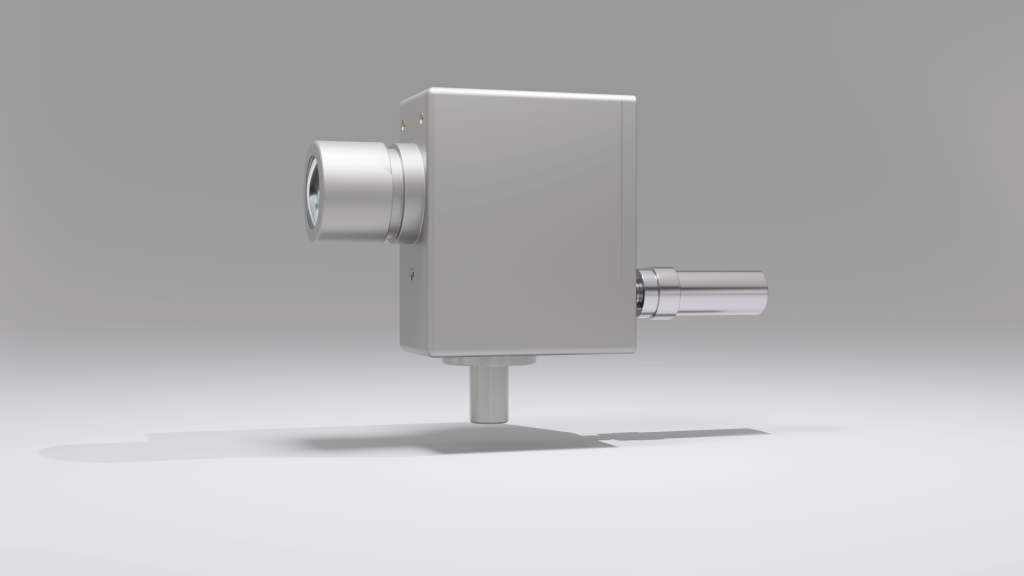

Infrared pyrometer

Non-Contact Temperature Monitoring in Real Time

Our infrared pyrometers provide accurate, contact-free temperature readings directly from your workpiece. Ideal for closed-loop control and data-logged quality assurance.

Smart Upgrades

Modernize Legacy Systems with Advanced Interfaces

The Smart Upgrade retrofits existing Himmelwerk systems with intelligent monitoring, data tracking, and interface connectivity — bringing older hardware into the Industry 4.0 era.

Cooling water recooling systems

Maintain Ideal Operating Temperatures

Standalone cooling units help manage thermal load and improve overall equipment lifespan. Our recooling systems are engineered for efficiency and easy integration.

Melting plants

Complete Systems for Controlled Metal Melting

Himmelwerk melting plants provide precise, repeatable melting processes for metals and alloys. Available in various sizes and power levels to match your production needs.

Induction Systems The Solution Provider

Himmelwerk provides optimal support, transparent communication, outstanding technology and industry know-how.